Malaga bacon: the secret of ramen in Japan

Faccsa -Prolongo. The Japanese market is now the third largest export destination for the local company

Nuria Triguero

Viernes, 2 de junio 2023, 10:38

In the huge meat processing plant of Faccsa-Prolongo, in Estación de Cártama, there is a part of the shop floor where the thickness of each slice of bacon is measured to the millimetre and there is a person in charge of removing any piece that does not meet the set measurements or the exact percentage of fat. The labels on the packages of deep-frozen meat display the destination for these pampered products: Japan. Furthermore, it is not uncommon to find a Japanese inspector monitoring this line. "Importers come every two weeks to conduct audits," explained Ramón Soler (junior), director of operations for this 200-year old company that claims to be the only one in Andalucía - and one of the few in Spain - selling pork to this Far Eastern nation.

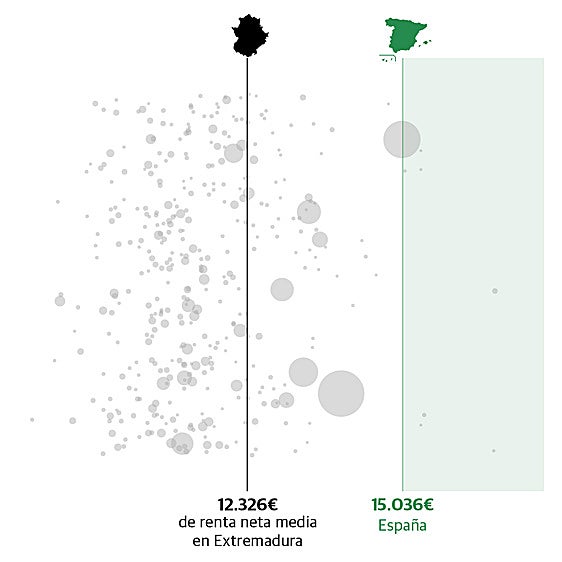

Japan has become Faccsa's third largest export destination. Sales to this highly demanding market are growing by 20% annually, with 2022 reaching sales of 25m euros (or 6m kilos by weight). Only the Spanish, French and Chinese markets exceed the land of the rising sun in turnover. Those 25 million, by the way, represent half of the total of goods exported from Malaga to Japan in 2022.

This large volume of exports rests almost exclusively on two products: bacon and pork loin, the raw materials to be braised as 'chashu', a key ingredient of ramen. "We are the largest European supplier to ramen restaurants," said Soler, who explained that in Japan there are several major chains with thousands of small establishments specialising in this popular dish.

Faccsa's bacon also has another culinary destination in Japan: marinated and smoked to become part of the 'bento' meal (individually-packed lunch-boxes with ready-to-go food that usually includes rice, fish or meat and a veg-based garnish or side-dish). These portioned trays, which make up the daily lunch or dinner for many Japanese, are sold in high street stalls, supermarkets and franchises. So, how did bacon 'made in Malaga' manage to become the star ingredient of street-food noodle soup in Japan? Ramón Soler admitted that the road was long and difficult. In 2001, this Cártama company obtained authorisation to export to Japan, but up to 2007 it had failed to sell a single slice of meat. "We went to trade fairs every year, but nobody bought from us. We didn't understand the market", explained the director of operations, who lived through that tortuous learning process firsthand as, at that time, he was responsible for exports. "We did not begin to understand it until all those responsible for the production process went to Japan and we scheduled a series of meetings with companies."

This is how they discovered several important things about Japanese culture: their obsession with perfection, for continuous process improvement; a zero tolerance for mistakes and an innate fear of germs and foreign materials or bodies getting into the production process. "You have to do things exactly as their protocol says: even if the result is perfect, if you have not followed the process to the letter then it doesn't count," explained Soler, who has a cover of the Japan Times recorded in his memory that he read on one of his travels: "They had closed a factory in Thailand of four thousand employees because a person had found a bit of a glove in a McNugget from McDonald's. It was a huge scandal."

At last they understood what the Japanese wanted. But another challenge remained: to 'Japan-ify' the factory. So for that they brought the people in charge of an importing company to Estación de Cártama. "We had them in the plant for a month: they reviewed the production process from top to bottom and told us how to adapt to their standards." The managers of the company make an important distinction here: it is a matter of the processes being different, not that Japanese sanitary and quality requirements are more exacting than those in Spain. The factory is already in compliance with Spanish regulations. "People don't have much of a clue as to the sanitary controls that exist in a slaughterhouse. Analyses are carried out daily on all production lines and every day we have Junta registered vets assigned to do a thorough job of inspection," they stated.

Now, Faccsa is reaping the fruits of all that effort. "The best-paid kilo of meat is in Japan," said the current sales manager for this market, Miguel Ángel Álvarez. Trade relations follow the highly regulated Japanese business method. "We do not sell to end-user customers, only to importers. There are just ten of them: mega-corporations with centuries of history and many different sectors: over there their names are as well-known as Yamaha or Honda...", said Soler. Along the way, Faccsa has also found another market niche: Japanese restaurants across Europe that also buy bacon and pork loin cut in the Japanese style.

Faccsa had a turnover of 280 million euros last year, of which 45% came from overseas trade. If Prolongo (with its cured and pre-packed meat products) and the transport subsidiary are added, the group's aggregate sales exceeded 300 million. This year the forecast is to surpass the 400 million, but not because of increased production, but because of the increase in prices. "The price for a live pig last year was at 1.05 euros per kilo and now it is at 2", explained Álvarez.

The company, owned by Ramón Soler and María Dolores Ciurana, exports to more than 25 countries and has more than 800 employees. It is deeply rooted in the town of Estación de Cártama, the municipality where its production plant is located and where it plans to build a new factory that will allow it to multiply that capacity.